AffordableHouse

DEVELOPER OF SUSTAINABLE INNOVATIVE HOUSING CONCEPTS.

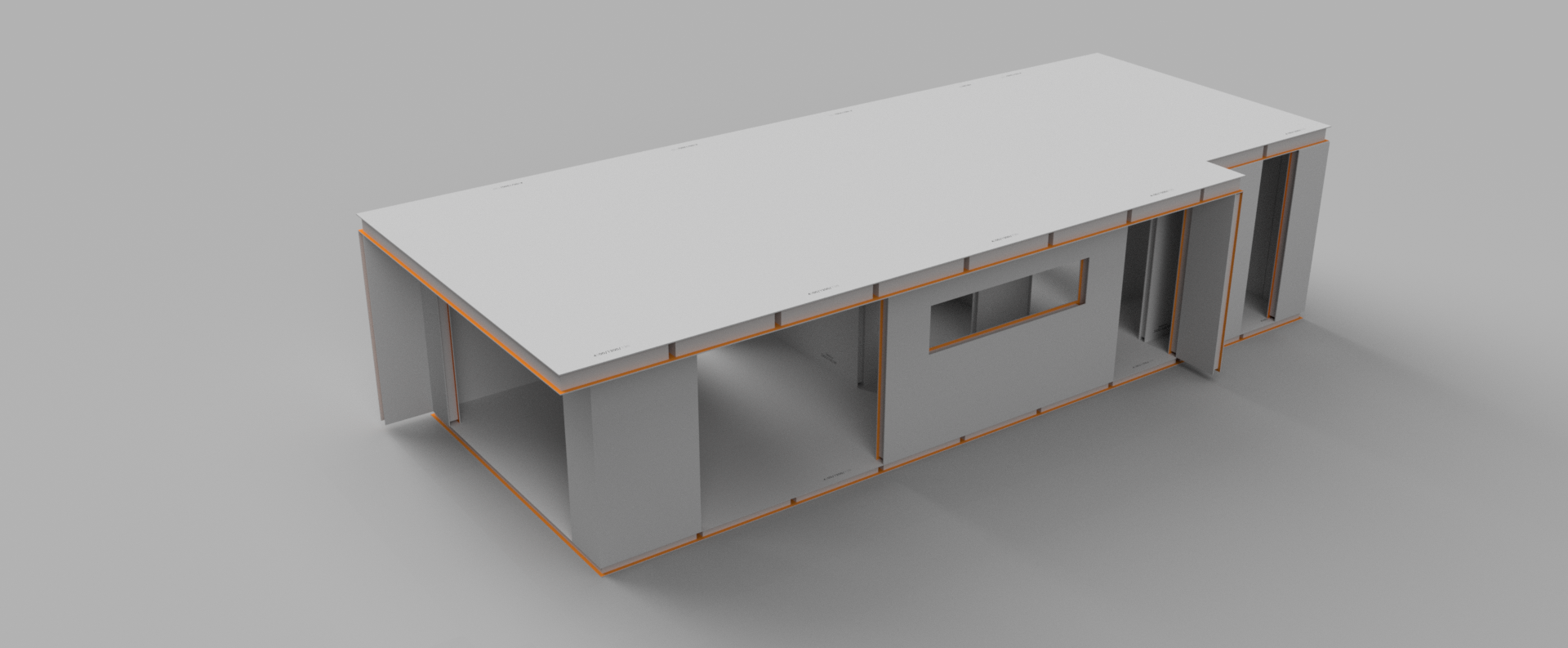

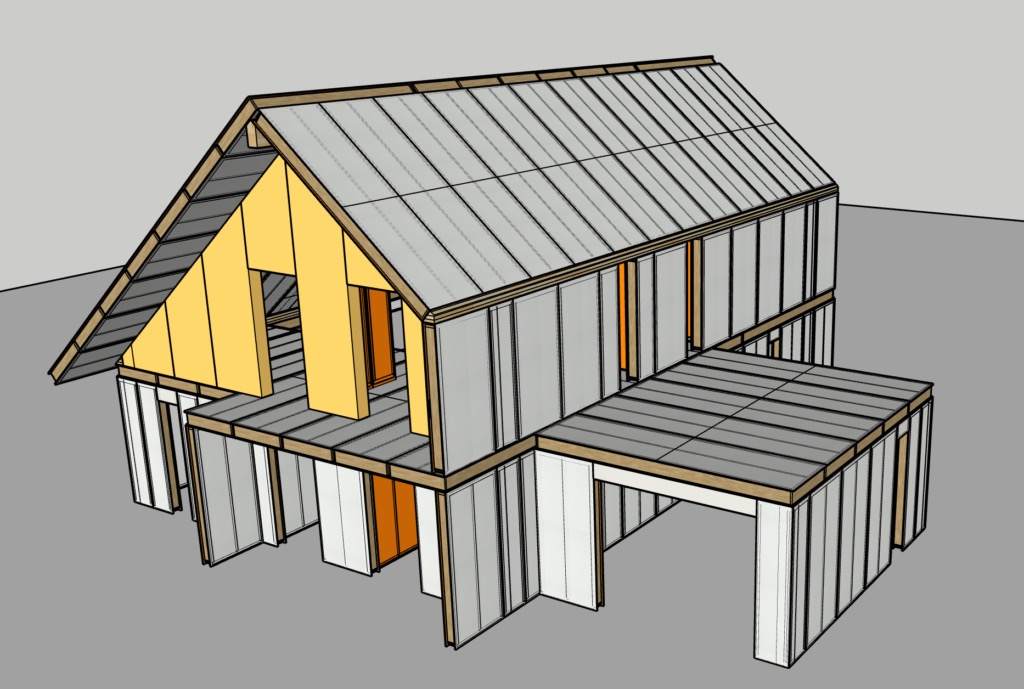

All our homes are built with the revolutionary NedPanel construction system. Not only does this modular construction system guarantee a high insulation value, short construction time and optimal protection against weather influences, but the house also offers construction-technical advantages that are not matched by traditional construction methods. Building with the NedPanel construction method is high-performance in all respects. Also in terms of carbon footprint and especially sustainability.

CARBON FOOTPRINT

LIGHTWEIGHT PANELS

NedPanel building elements compared to traditional concrete or stone construction, a much lighter foundation can be used. Depending on the type of home or the soil composition on site, we generally use three foundation systems for our homes:

- Foundation on Steel; a reinforced concrete floor poured on an insulated EPS/XPS insulation layer with a thickness of at least 200mm.

- Suspended; the NedPanel floor elements of the house are placed and fixed on a modular steel frame of C-Profiles. The metal frame is supported by galvanized screw piles and is placed 15-20 cm above the ground.

- Floating; due to the relatively low weight of the NedPanel elements, the houses are also very suitable for floating foundations and pontoons.

SIMPLE CONSTRUCTION

By using standardized dimensions of the elements and the integration of pipes into the panels, building in the “NedPanel way” is made significantly easier compared to traditional construction. This not only greatly reduces construction time, but also takes advantage of the need for professional builders and installers to finish the home. Not only are they expensive, they are becoming increasingly difficult to find. The NedPanel building system makes building easier, cleaner, fast, but above all affordable.

MODULAR CONSTRUCTION

The relatively small dimensions of the NedPanel elements make it easy to build with individual elements even in hard-to-reach locations. It is also possible to prefabricate the houses into almost finished wall/roof elements or as plug and play building modules. The modules are easily stackable up to 3 building layers. If taller buildings are desired, the modules can be installed in combination with modular steel or concrete structural frames.

Emission-free Construction Site

Another additional advantage of the low weight combined with the relatively small dimensions of the NedPanel building elements results in the possibility of assembling the homes exclusively with electric-construction machinery and tools. This allows the houses to be built on site completely emission-free. It is even possible to build the houses completely “off the grid” with a mobile battery pack.

Construction System

ALL-IN-ONE SOLUTION

The patented NedPanel building element is more than just a “large building block.” NedPanel’s all-in-one element combines the following features in one product:

Structural element applicable as floor, interior and exterior walls and roof.

High insulation value through the use of PIR insulation.

Extremely suitable for airtight construction.

Suitable for almost all facade finishing materials both indoors and outdoors.

Wall construction with A1 class fire-resistant cladding panels.

Integration of plug-in electrical wiring.

Integration of cold and hot water lines.

Integrated vapor barrier on the interior wall.

DESIGN PHILOSOPHY

Facade finishing:

Both the interior and exterior cladding of NedPanel building elements are made of Magnesium Oxide (Mgo). This is a cementitious, fiberglass-reinforced construction board that is not only resistant to the Dutch weather but is also fire-resistant. Unlike the OSB sheeting commonly used in timber frame or SIP construction methods. The NedPanel system is built to last as long as concrete, but without the massive pollution caused by the cement industry.

NedPanel elements are constructed with standard widths of 60 cm or 120 cm. The building elements are produced in standard lengths. Our complete housing line is designed so that homes are built exclusively with standard panels. This results in maximum efficiency on the construction site and “clean” construction without waste. Not only are the building elements based on these dimensions, the windows, doors and various façade finishes are also based on these dimensions. This allows the houses to be easily configured or modified without time-consuming-and often costly-procedures with architects or structural engineers.

This ensures maximum efficiency throughout the entire construction cycle, from the design phase to the delivery of the home.

Nederlands

Nederlands